& industrial

DELT – ATG Plus – Underground Tank Oil Level Measurement System, an advanced system for monitoring oil levels and detecting leaks in underground tanks, supporting both Thai and English. Ideal for service stations, it enhances inventory management with precise data. Key features include alerts via computer or mobile devices through the iTANK app (compatible with ANDROID and iOS), providing quick access to data from anywhere with an internet connection for effective decision-making.

DELT SYSTEM’s new automatic gauge enhances fuel stock management at service stations by providing accurate, real-time monitoring of underground oil tanks. It eliminates the need for manual measurements, preventing errors and ensuring up to 99.9% accuracy. The system offers continuous surveillance and alerts for issues like water ingress, low oil levels, and overflows, ensuring efficient and reliable operation. Before installing the underground oil tank level measurement system, please review the details, requirements, and safety standards of the equipment and installation process. This will ensure you can fully benefit from the ATG system.

SS160PLUS

The SS160Plus is the entry-level oil measurement system from DELT SYSTEM, offering a dual-language interface in Thai and English. It is cost-effective and supports measurements for up to 9 tanks, utilizing the DELT-SS series control panel. The system features a multifunctional platform on a 8-inch color touch screen, providing highly accurate and reliable data processing. This enables efficient and cost-effective oil stock management. The touch screen interface has been endorsed by thousands of service station owners. Whenever you need inventory data, delivery planning, and accurate sales management, the DELT-ATG system meets your requirements.

SS200A

The SS200A is the latest oil measurement system from DELT SYSTEM, featuring a dual-language interface in Thai and English. It is available in three versions, supporting measurements for 8, 12, and 16 tanks. The system offers a multifunctional platform compatible with all types of leak prevention systems, including double-walled tanks and pipes, tank-sump vapor recovery, and electrostatic discharge protection. It has an 8-inch vibrant touch screen with status indicator lights for various functions. The system provides highly accurate data processing, enabling efficient oil stock management. This model is ideal for service stations requiring integrated management and safety control systems.

SS200B

The SS200B is the premium oil measurement system from DELT SYSTEM, featuring a dual-language interface in Thai and English. It is cost-effective and supports measurements for up to 32 tanks. The system offers a multifunctional platform compatible with all types of leak prevention systems, including double-walled tanks and pipes, tank-sump vapor recovery, and electrostatic discharge protection. It has a 12-inch color touch screen with high accuracy data processing capabilities, enabling efficient oil stock management. This model is ideal for service stations requiring integrated management and safety control systems, without budget constraints.

SS200A Wireless

The latest DELT Wireless ATG connects using long-range wireless communication with the new LoRa Modulation Technology. This M2M (Machine to Machine) solution allows devices to exchange data seamlessly. It is ideal for service stations wanting to install an ATG system without running cables or drilling through existing concrete. The system supports data transmission over distances up to 500 meters and is compatible with IoT (Internet of Things). It features an easy-to-read, customizable display that supports both Thai and English.

SP300 PROBE

The SP300 PROBE is a magnetostrictive oil level measurement probe utilizing the Wiedemann effect, Villari effect, and ultrasonic effect of smart materials. It measures time differences with high accuracy to convert them into displacement differences, allowing for precise measurement of product levels, water levels, and temperature in tanks.

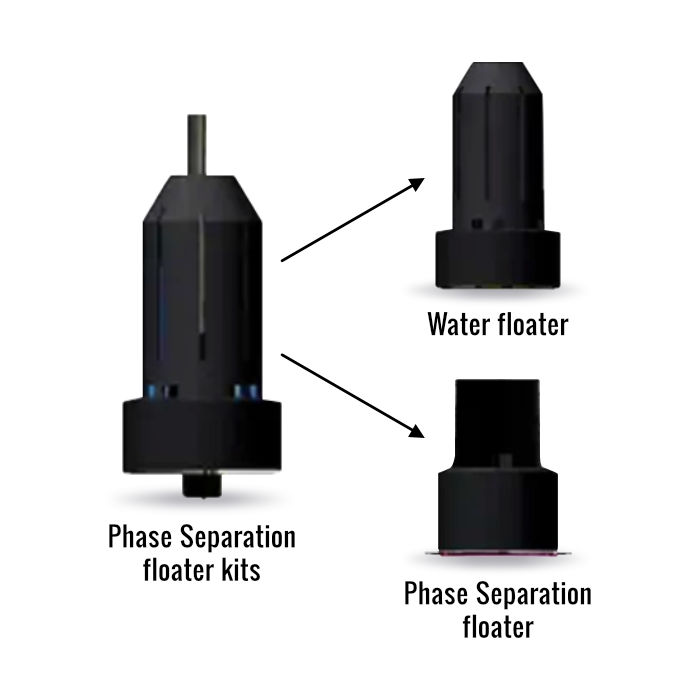

Special floats are available for various purposes, such as density floats and phase separation floats for detecting ethanol stratification in E20 and E85 fuels.

Phase Separation Float

DELT Ethanol Phase Separation Detection in E20 or E85 Gasoline, when water enters a tank containing a gasoline/ethanol mixture, the ethanol absorbs the water, causing it to separate from the gasoline and sink to the bottom of the tank, mixing with the water. This ethanol-water mixture (phase separation) is denser than pure water and cannot be detected by traditional floating probes. Special floats are designed to detect varying densities to identify phase separation at the bottom of your underground tank. If undetected, this mixture may be pumped into customers’ vehicles, leading to engine problems and potentially incurring repair costs, filter replacements, and contaminated fuel disposal. Ethanol blending increases octane levels, but when ethanol mixes with water to create phase separation, the remaining gasoline’s octane level drops, potentially leading to legal issues with selling non-compliant fuel.